What is the differences and relations between viscosity and yield value?

viskozite verim oranı işlemiş olduğunuz ürüne göre değişir.Konsantre işliyorsanız misal kapasiteniz yüksektir ama işlem sonundaki viskozite arttık sıra işletme üretim veriminiz düşer. NFC meyve suyu yaparken direk viskozite düşük olduğu için nihayi ürün üretim kapasiteniz daha yüksektir.

sorunuzdan çıkardığım anlam bu.Başka bir kastınız varsa soruyu detaylandırmanız gerek.

Please in English.

my understanding is this way:

viscosity is the resistance to flow, which means if something is very resistant to flow it is more viscous than the other liquid that flows easily (eg, sauce versus water).

Yield value can be simply explained using a newly purchased bottle of tomato sauce, where we always take this bottle in our hand, hold upside down and give a ‘bang’ or ‘hit’ and that is the stress required for an initial flow of fluid to start with - which is termed as the minimal yield value required for this sauce… please expand or correct me also.

That’s a concise explanation …Thanks.

There is a Casson viscosity and yield value which are used to control chocolate quality though the control in the amount of fat or through emulsifier like lecithin, ammonium phosphatides,polyglycerol polyricinoleate PGPR.A chocolate having the proper balance of emulsifier will be tested rheologically to determine if they are either fit for coating (enrobing) or casting .

I think our new member @foodspecialist can show us some good points

Dears i can only support what @Roy has mentioned above with a base example on chocolate manufacturing

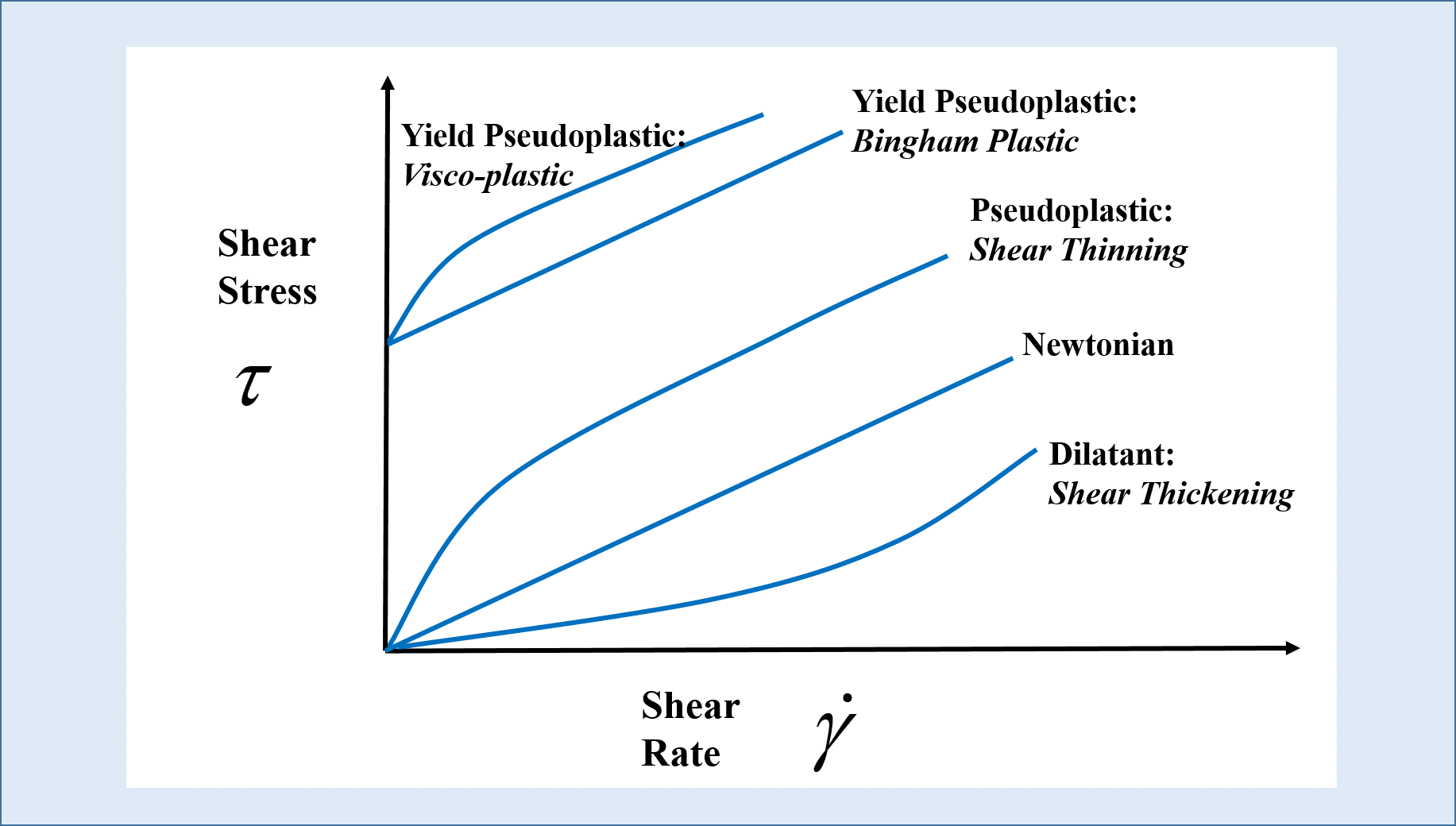

First viscosity and velocity topics should be covered perfectly in fluids and their rheologies to make comments and/or solve and process related problems. You should know whether you are working with newtonian or non newtonian fluids . Both has different understanding on viscosity ( shear rate, shear stress) , yield value (for only non newtonian) and velocity. Also this is very important to choose true process equipment.

Viscosity is amount of force that has be to exerted to maintain constant flow . Imagine 3D plates of chocolate mass , you can easily realize opposite forces against flow , this is viscosity. You can decrease this with true fat ratio and lecithin.

Yield value is amount of force that initiate flow . It is a level of force where flow starts . There is no meaning of yield value when you achieve to start of flow . You can adjust this with true particule size of mass (milling process) and PGPR !

For enrobing on a food product, if you can not cover enough this two parameter, you can not adjust your enrobing or decorating units.

force between layers which control flow. Am i right ?

ok. For which process, yv is critical , can you give us an example ( coating, moulding or ) ?

Absolutely…

For chocolate enrobing any food staffs like fondant, nougat, cakes etc , yield value is too critical. For example you coated a cake and cooled . Let’s say you cut product after cooling and check thickness equality and you see thickness differences and even some gaps on corners. You can easily assume that yield value is not correct on process

For molding , viscosity is critical. This is depending on many acts that we can discuss;))

Great example i got it.

So, as on your above example about yield value; If yv is not OK do not we have some problems about moulding, Mould corners ? And, does not yv effect of diffusion character of chocolate in mould ? Especially with small moulds and logo shaped moulds.

İ dont think that you will face a problem with yield value on molding line either it is small or big molds . Because , today molding lines (inline systems or others) are generally equipped with pneumatic depositors and vibrators and cylinder scrapers. They have enough mechanical force more than mass flow requires to start flow or spread . As you know one flow or diffusion stars with any force, than viscosity will take roles.