Many foods are very sensitive for oxygen, which is responsible for the deterioration of many products either directly or indirectly. In fact, in many cases food deterioration is caused by oxidation reactions or by the presence of spoilage aerobic microorganisms. Therefore, in order to preserve these products, oxygen is often excluded.

Oxygen (O2) presence in food packages is mainly due to failures in the packaging process, such as mixture of gases containing oxygen residues, or inefficient vacuum. Vacuum packaging has been widely used to eliminate oxygen in the package prior to sealing. However, the oxygen that permeates from the outside environment into the package through the packaging material cannot be removed by this method .

Modified atmosphere packaging (MAP) is often used as an alternative to reduce the O2 inside food packaging. However, for many foods, the levels of residual oxygen that can be achieved by regular (MAP) technologies are too high for maintaining the desired quality and for achieving the sought shelf-life . The use of oxygen scavenging packaging materials means that oxygen dissolved in the food, or present initially in the headspace, can potentially be reduced to levels much lower than those achievable by modified atmosphere packaging .

In this context, research and developments in the food packaging area have been conducted, aiming to eliminate residual O2. One of the most attractive subjects is the active packaging concept. Active packaging includes oxygen and ethylene scavengers, carbon dioxide scavengers and emitters, humidity controllers, flavor emitters or absorbers and films incorporated with antimicrobial and antioxidant agents .

The most used active packaging technologies for food are those developed to scavenge oxygen and were first commercialized in the late 1970s by Japan’s Mitsubishi Gas Chemical Company (Ageless®). In the case of gas scavengers, reactive compounds are either contained in individual sachets or stickers associated to the packaging material or directly incorporated into the packaging material .

The first patent of an absorber was given in 1938 in Finland. This patent was developed to remove the residual oxygen in headspace of metallic packaging. The method of introduction of hydrogen gas in the packaging to react with oxygen in palladium presence was commercialized in 1960s however this method has never been popularized and well accepted because the hydrogen was unstable during manipulation and storage and, furthermore, it is expensive and unwholesome . Recently, more than 400 patents were recorded, mainly in EUA, Japan and Europe, due the great interest by absorbers use .

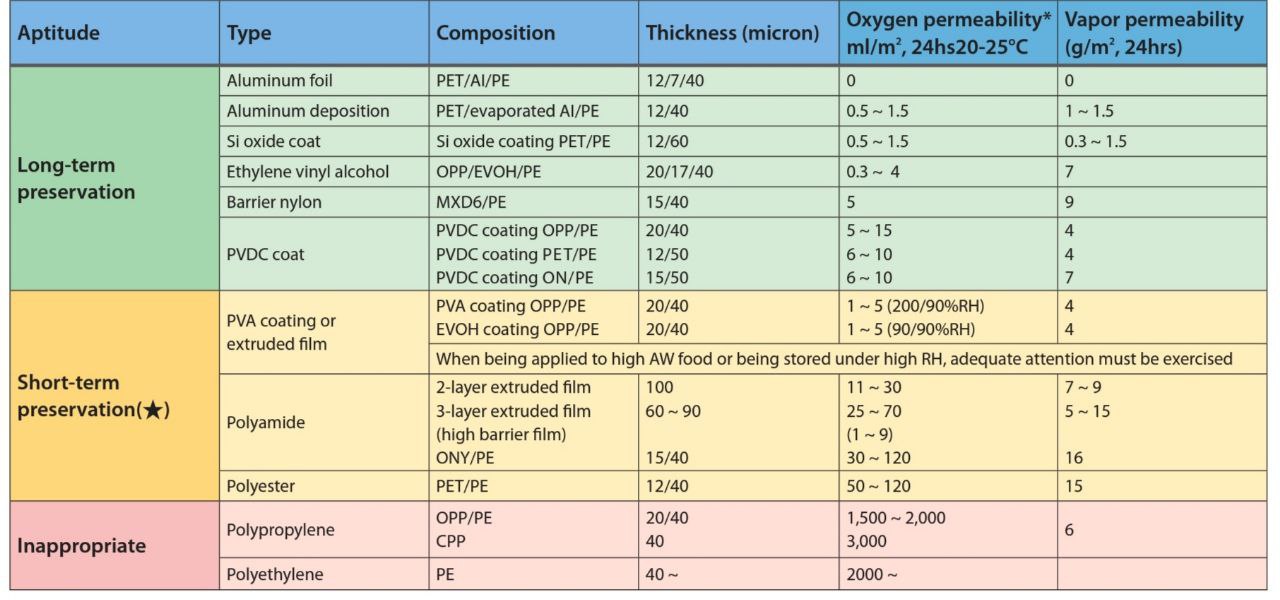

Oxygen scavengers are becoming increasingly attractive to food manufacturers and retailers and the growth outlook for the global market is bullish. Pira International Ltd estimated the global oxygen scavenger market to be 12 billion units in Japan, 500 million in the USA and 300 million in Western Europe in 2001. This market was forecast to grow to 14.4 billion in Japan, 4.5 billion in the USA and 5.7 billion in Western Europe in 2007 . In addition, Pira International Ltd. estimated the global value of this market in 2005 to be worth $588 million and has forecast this market to be worth $924 million in 2010. The increasing popularity of oxygen scavenging polyethylene terephthalate (PET) bottles, bottle caps and crowns for beers and other beverages has greatly contributed to this impressive growth .

Download the full article.

Oxygen Scavengers An Approach on Food Preservation.pdf (806.6 KB)

Renato Souza Cruz, Geany Peruch Camilloto and Ana Clarissa dos Santos Pires (August 22nd 2012). Oxygen Scavengers: An Approach on Food Preservation, Structure and Function of Food Engineering, Ayman Amer Eissa, IntechOpen, DOI: 10.5772/48453. Available from: https://www.intechopen.com/books/structure-and-function-of-food-engineering/oxygen-scavengers-an-approach-on-food-preservation