Pasta, which is widely consumed in the world and in our country, is an important food item. The most important feature that distinguishes pasta from the other dough products is hard and glassy structure of the wheat.

The most important feature of the pasta is the reaction of the unsaturated fatty acids and oxygen in the presence of lipoxygenase enzymes in the presence of oxygen during the kneading process.

The pasta dough is carried out in two stages as pre- and main drying. The main reason for the pre-drying is the drying of the dough at high temperatures during the main drying process. At the same time, pasta drying process is carried out at high temperatures with an industrial system. One of the main reasons for the drying of pasta dough at high temperatures is the need for high capacity and the other reason is to prevent amylotic activity from forming a sticky product.

Drying is one of the most important techniques in the food industry. The drying process is aimed at reducing the bacterial load of foods with high biological activity and increasing the shelf life.

Drying is an important process for pasta.

Drying process on the surface of the pasta takes place with two physical events.

- Water diffusion of solid matrix of pasta, water coming to product and air interface

- Forced transport to the air through the interface

This is a model to measure the drying efficiency and to determine the parameters of the drying process and the accuracy of the model is checked by comparing this model with industrial systems.

With the developing technologies and software, determination of these processes and accuracy rate has increased. With computational fluid dynamics (CFD), designing and measuring the effectiveness of systems such as mixing, evaporation, drying in the food industry will be even more important in advancing technologies.

In our study, a simple static pasta dryer has an air temperature of 0.005 m / s moisture content of 68% and pasta moisture content of approximately 30% air temperature is determined as 358 kelvin.

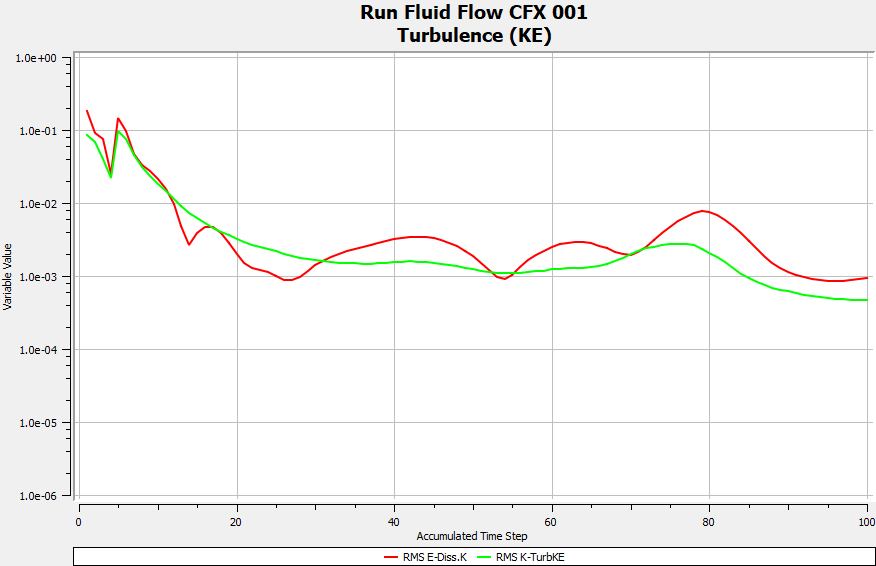

Static desiccant was analyzed by Ansys R 19.2 academic and equation analysis was performed in k-epsilon. The data are obtained below.

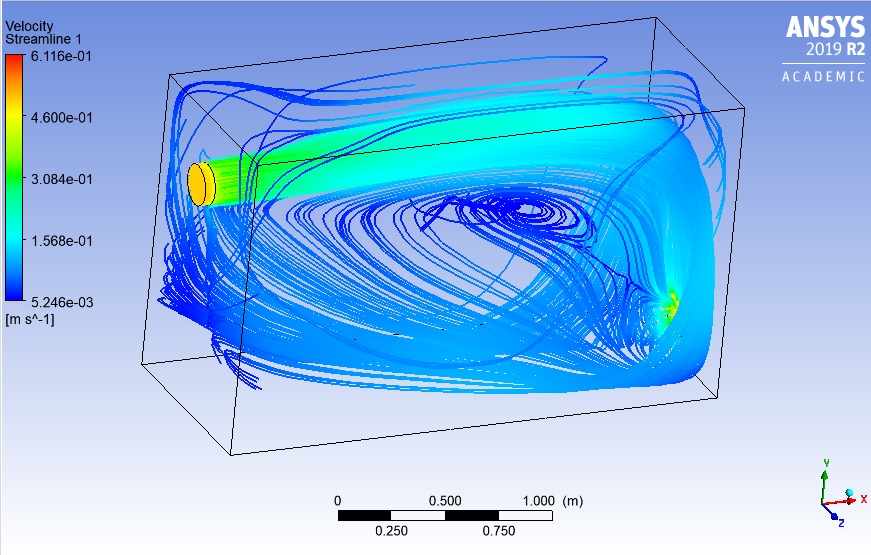

The distribution of air in the system is shown in the figure below. The air inside absorbed the moisture on the pasta and completed the drying activity.